Super User

EDA INDUSTRIES Asia Pacific Pte., Ltd.

EDA INDUSTRIES (Asia Pacific) Pte., Ltd. SINGAPORE

Asia HQ, Production, Service Center,

Application, Reliability and Burn-In Service Center

8 Lor Bakar Batu, #06-12,

SINGAPORE 348745

Tel: +65 6741 1768 Fax: +65 6741 1769

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

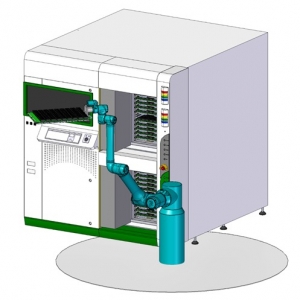

Automation

When you begin working on the development of an automated Burn-in area there are a lot of argument to be coordinated and consolidated: Automatic Bib warehouse, AGV fleet management, SW, etcc. For these reasons it might be preferable, more practical, to choose the most flexible solution in the market: The COBOT.

- Equipped with a light ring, it immediately signals its status or draws the attention of operators.

- Clean room ISO 14644-1 Class 6 certified, and protection from dust and water splashes IP54.

- Advanced security level PL e - CAT 4.

- Smart-Vision system

- EASY INSTALLATION in many different directions (front of the Chamber, in the roof, sideways, dedicated AGV….)

For info, pls send a direct request to This email address is being protected from spambots. You need JavaScript enabled to view it..

Wafer Level Burn-in

By interpreting SiC and GaN mega-trend, EDA designed SocrATE project, putting in place all the skills to develop an exclusive product, in line with the expectations of the AUTOMOTIVE market such as Testing Coverage, Quality and lowest Test cost.

System features

SocrATE is a complete Burn-in test system designed specifically to meet the needs of cost-sensitive volume manufacturing of current and next generation SiC, GaN and High Voltage devices.

SocrATE offers true site-independent test across a broad range of software-controlled configurations. The innovative architecture backs each of the system's 1800 or 3600 sites with a fully independent Test system.

Prober

The proposed Prober technology with common Loader and Unloader solution is composed by:

5cell MS-WLBI system with:

- 1 common loader/unloader for the complete System

- Probe card clamping system up to 520mm

- Cassette docking port (FOUP) for 6" and 8"

- ZERO Footprint Manipulator

- 6" and 8" Bernoulli handling system

- Room temperature to hot control (Room temp ~ 250'C)

- N2 supply solution for chamber

- 6" & 8" Wafer size chuck for 6" SiC wafer and 8" TAIKO wafer (Gold plating, Multi hole, w/o 3pin riser)

- SECSGEM Automation

Tester

EDA philosophy has always been oriented towards the needs of Customer using cutting edge solutions to produce practical and easy to use products which are constantly upgraded over time.

In particular for this purpose we can offer a range of 2 Tester configurations specially created for the MS-WLBI Equipment.

1- Basic Tester for Burn-in stress on 1800 Dice, called AWL-BITS 1800.

2- Upgrade for Burn-in stress on additional 1800 Dice for a total of 3.600 Dice in parallel, called AWL-BITS 3600.

EDA Tester proposal has a modular true site-independent test architecture based on a BASIC electronic configuration to perform a typical Burn-in stress on 1800 Dice in parallel.

This Basic platform can be upgraded over time to increase the Burn-in capacity up to 3.600 Dice in parallel.

Every Cell has its own Tester to perform an independent Test Flow including stress sequence up to 2500V and parametric test sequence (Vth, BVDss, IDSX and IGSS).

Software

The system's enhanced SW Test Environment provides the complete set of software tools for Test development (SW Development package), Production execution and Reporting (SW Execution package).

To speed devices to market quickly, the AWL-BITS software provides the engineering tools necessary to characterize devices as well as develop and debug test programs quickly and efficiently.

AWL-BITS has a rich set of interactive, graphical user interface (GUI) based development, debug and production.

Dimension and Workcell Area

The combination of high performance architecture and compact design enables the AWL-BITS to provide the industry's highest unit volume per square foot well beyond any other system.

The system provides twice parallelism in half the Workcell area than any standard Test Cell.

Environmental Stress Screening System

In 2005, one of the world’s leading manufacturers of railway signal control equipment asked us to go beyond the supply of a machine capable of satisfying the thermal gradient and temperature range

requirements with the goal of obtaining an integrated system capable of automating tests ... and the result was a “custom” ESS TC2.6.

Since then, the machine’s feature of automation and “flexible” electronics capable of adapting to the processes of multiple product lines has made it one of the most popular and successful systems produced by the EDA Industries’ engineering division for Environmental Chambers.

Main Features:

- One 2600 litres thermal chamber

- Automatic pneumatic UUT Rack insertion/extraction

- Custom test electronic cabinet (Simulator Rack)

- Dryer

- -30 °C to +90°C (with Contact Fixture)

- -70 °C to +180°C (extended range without fixture)

For direct request, pls contact This email address is being protected from spambots. You need JavaScript enabled to view it.

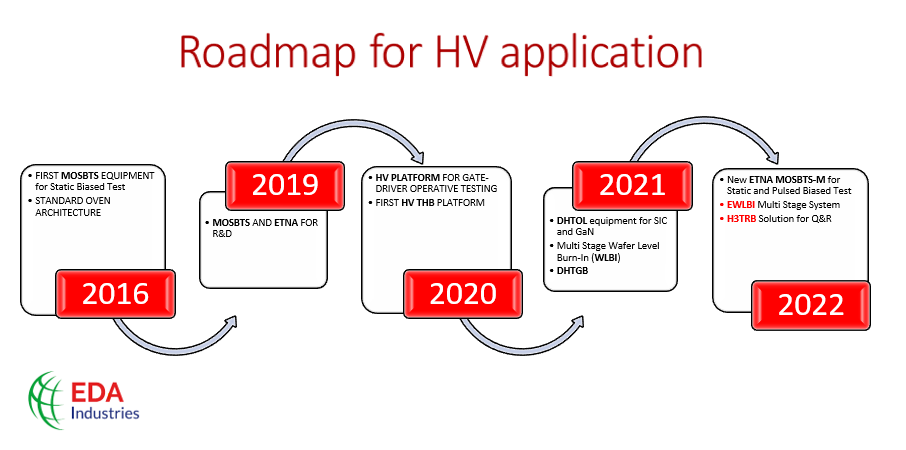

Dedicated products for SiC and GaN

MOSBTS-M on ETNA platform enables many different Test executions for SiC and GaN, discrete and Power Modules:

- HTRB/HTGB

- H3TRB

- DHTOL

- LTOL

- PTC

More than 50 ETNA MOSBTS -M are currently installed in Mass Production.

For info, pls send a direct request to This email address is being protected from spambots. You need JavaScript enabled to view it..

Test Equipment

In addition to the test systems and burn-in, EDA Industries produces a series of equipment to manage the other operations of the electronic devices' qualification and production cycles.

Those products are:

- Engineering Test Station (ETS)

- Pre Burn-in Test Station (PBTS)

ENGINEERING TEST STATION (ETS)

Description:

ETS stays for Engineering Test Station.

It is meant to be used for Application Development, BIB design debug, Test program verification, etc.

It gives a direct access to the top of the Burn-in Board to easily insert/remove device, running/stopping tests, measuring voltages, currents, waveform, etc. directly on the BIB while the test is running.

The top roof/tray of the equipment can comfortably hold devices, oscilloscopes, multimeter, logical analyser or other measurement instrumentation or tools.

Alternatively, instruments can be on a rack positioned aside the station.

The user can stand in front of the BIB, or sit in front of the display/keyboard.

Electronics:

The ETS can be equipped with any EDA test electronics, like the latest UBTS/VBTS, MBTSIII, DFTB, with options like:

Individual DUT Temperature Control, Parametric Test capability, High Power option.

ETS can be also equipped with EDA former electronics, like DBTS, HBTS, MBTS, or even with CUSTOM ELECTRONIC.

Software:

The system's SW is the EDA HD6, in its Basic or Enhanced version.

It is the same SW running in the Burn-in System (oven), of course without the control of any chamber.

Other SW packages are usually installed in the ETS, like EDA DataViewer, EDA Test Plan Editor, EDA Pattern Converter, etc...

For info, pls send a direct request to This email address is being protected from spambots. You need JavaScript enabled to view it..

PRE-BURN-IN TEST STATION (PBTS)

Description:

PBTS stays for Pre-Burn-in Test Station.

It is meant to be used for BIB verification before the Burn-in.

The test can be done AFTER the BIB loading, or DURING the BIB manual loading, using this equipment as a Manual Loading Station with Functional and/or Parametric Test.

It gives a direct access to the top of the Burn-in Board to easily insert/remove devices to troubleshoot eventual DUT loading issue, BIB or fuses issues, etc.

This operation can be executed during the normal runtime of the OVEN, getting the BIB ready and fully functional for the next run, maximising the throughput, optimizing the operations and reducing the Oven set up time.

The top roof/tray of the equipment can comfortably hold devices to be loaded, and other trays to sort out the failing devices.

The user can stand in front of the BIB, or sit in front of the display/keyboard.

A PBTS used as Manual Loading Station can be equipped with a foot-pedal to start a Test During Loading by using the foot while the hands are used for DUT handling.

Electronics:

The PBTS can be equipped with any EDA test electronics, like the latest UBTS/VBTS, MBTSIII, DFTB, with options like:

Individual DUT Temperature Control, Parametric Test capability, High Power option.

PBTS can be also equipped with EDA former electronics, like DBTS, HBTS, MBTS, or even with CUSTOM ELECTRONIC.

Software:

The system's SW is the EDA HD6 (in its Basic or Enhanced version) or the Manual Loading Station dedicated SW.

HD6 is the same SW running in the Burn-in System (oven), of course without the control of any chamber, with additional functions for PBTS.

For info, pls send a direct request to This email address is being protected from spambots. You need JavaScript enabled to view it..

Burn-in and Environmental Chambers

EDA Industries is leader on Burn-in and Environmental Stress Chambers for semiconductor devices and electronic products.

The ETNA system summarizes 30 years of experience. It is the ideal platform to carry out R&D, Q&R and production tests for the main families of devices.

The devices that can be tested with ETNA platform include High voltage devices, System on Chip (SoC), Micro Electro Mechanical Systems (MEMs) and Memories. Within the family of SoC devices, EDA is focused on Smart power, Logic SoC and SoC with embedded memory. For High Voltage we have a specific platform called MOSBTS-M Test System.

In addition to the significant existing products' portfolio, EDA Industries is specialized in meeting specific customer requests by customising its products or by designing new ones.

Our Sales team and the highly specialised Technical department will be at your disposal to discuss any technical topic.

For direct requests, pls contact This email address is being protected from spambots. You need JavaScript enabled to view it..

Our Chambers

- SM12: Single Chamber, 12 slots, Manual insertion/extraction

Options: COLD, HOT, PTC, Individual Dut Temperature Control - SM24: Single Chamber, 24 slots, Manual insertion/extraction

Options: COLD, AIR, Individual Dut Temperature Control - SA24: Single Chamber, 24 slots, Automatic insertion/extraction

- DM24: Dual Chamber, 24 slots, Manual insertion/extraction

Options: COLD on Ch2, HOT, Individual Dut Temperature Control - DA24: Dual Chamber, 24 slots, Automatic insertion/extraction

Options: COLD on Ch2, HOT, Individual Dut Temperature Control - QM24: Quad Chamber, 24 slots, Manual insertion/extraction

- DM48: Dual Chamber, 48 slots, Manual insertion/extraction

- DA48: Dual Chamber, 48 slots, Automatic insertion/extraction

- QM48: Quad Chamber, 48 slots, Manual insertion/extraction

Options: 175°C, 210°C - DM12-HP: Single Chamber, 12 slots EDA HD-HP, Manual insertion/extraction

for High Power applications with Individual Dut Temperature Control - SM12 Enhanced OLT: Single Chamber, 12 slots Enhanced, Manual insertion/extraction

Power/Load architecture, Enhanced Analog Stimulation and Monitoring, External PSU - SM12 Enhanced PTC: Single Chamber, 12 slots Enhanced, Manual insertion/extraction

Power/Load architecture, Enhanced Analog Stimulation and Monitoring, External PSU - OPUS100 OLT/PTC: Single, Dual, Quad chamber, for 12-24-48 slots with Manual insertion/extraction

Power/Load architecture, External PSU - SM12-THB/HTRB: Single Chamber, 12 slots, Manual insertion/extraction,

with Humidity and/or Cold Option - ERIS-THB/HC: Single Chamber, with Humidity Option

for Damp Heat Test or with Cold Option for Hot & Cold Test

- E.S.S. TC2600: Single Chamber Environmental Stress and Screening System

- TC 1200/440: Thermal Cycler for 80Kg

- PTC: Power and Thermal Cycler

Product search

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur rhoncus nulla a mi tempus eget mollis orci scelerisque. Praesent orci urna, aliquet sed euismod sit amet, placerat eget ante. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Nunc tellus neque, volutpat

Footer IT

EDA INDUSTRIES GROUP - Eda Industries S.p.A. - Production & Headquarter Via dell'elettronica snc, 02015 Cittaducale (RI), Italy. Società con unico socio; Direzione e coord. di Eda Holding S.r.l., REA 50954, Reg. impr. di Rieti, P.Iva/C.F.: 00640600557, cap. soc. 493.420,00 euro i.v., Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Dynamic Burn-In Systems, Burn-In And Test Systems, Burn-In Chambers, Burn-In Boards, Hast Boards, 85/85 Boards, Test Equipment For Semiconductors, S.S. Systems, Engineering Test Stations, Data Acquisition Systems, Instrumentation Racks, Customized Testers For Electronic Modules, Climatic Chambers, Standard Ovens, Clean Rooms Ovens, Thermal Cycler, Process Control, Automation, Software Package. Cookie policy | Privacy policy

Test Electronic for Burn-in System

UBTS / VBTS / VBTS-M Series

Starting with dedicated BI system for Memories, Digital, Automotive and Mixed-Signal devices, the technological evolution of devices dictated by the market and the demand of increasing the test capacity have brought EDA Industries to design a powerful and innovative test system: the UBTS - Universal Burnin Test System.

This series is based on reprogrammable Microprocessor and FPGA firmwares, so that the same HW platform can be SW reconfigured as a Digital, Mixed-Signal, Memory tester.

Moreover, it allows a continuous development of new features and upgrades, that can be easily released/updated just by deploying a FW release.

EDA has continuously developed its main BurnIn systems introducing many features and improving roboustness in order to offer a state-of-art Test Electronic for the BurnIn.

Driving the evolution since UBTS, through VBTS, and finally to its latest modular version: the VBTS-M.

Main Features:

-

- advanced modularity for an easy system configuration and improved maintenability

- up to 256 I/O Bidirectional lines

- up to 48 Stimulation lines

- additional 32 Input lines

- up to 6 DUTs Power Supply Units, powering each BIB with up to 600W and 104A.

- 4 VREF for DUT Voltage References

- 32 EXT lines for optional boards, ensuring function expandability and customization.

Options:

-

- Analog Waveform Generator board, adding 4 differential Analog channels.

- Analog Monitoring board, replacing 128 IOs with 96 Analog Input lines, monitored by windows comparation.

- High Power option, bringing additional 16 High Power Supplies dedicated for DUTs' supply, powering each BIB with more than 2KW and 640A.

- DUT TEMP MON option for Single Device Temperature Monitoring, fully embedded in the EDA system.

- Single-Device Temperature Control option, fully embedded in the EDA system.

- Parametric Measurement option, adding PMU capability to every line and power supply.

- Enhanced option for advanced Quality and Reliability Test, bringing arbitrary waveform generation, advanced analog monitoring, and a 5KW external power supply control with 24 EXT-PSU lines for independent voltage and current monitoring.

- Enhanced option for Power/Load architecture, bringing an additional 5/10KW External Power Supply to test devices that require external fixed or programmable load.

Compatibility:

-

- to replace the existing systems with the new platform while keeping in use the existing BIBs VBTS-M Series ensures the compatibility with

- the other EDA BIB standards: DBTS, HBTS, MBTSII, MBTSIII, ARES

- many non-EDA BIB standard: Standard-A, Standard-C, AHER-MAX, ART-200, UAMT, ADBV1, EJ18/EJ22, ENDZONE, CRITERIA.

- ... ask us to make your BIB standard compatibile with the state-of-the-art EDA BurnIn platform...

- to replace the existing systems with the new platform while keeping in use the existing BIBs VBTS-M Series ensures the compatibility with

DBTS / DBTS-LV / DBTS-A / HBTS / MBTS

They are our original solution for Digital, Hybrid, Automotive and Memory devices.

Now covered by our Universal BurnIn and Test platform: the newest VBTS-M series.

For info, pls send a direct request to This email address is being protected from spambots. You need JavaScript enabled to view it..