EDA Industries is leader on Burn-in and Environmental Stress Chambers for semiconductor devices and electronic products. The ETNA system summarizes 30 years of experience. It is the ideal platform to carry out R&D, Q&R and production tests for the main families of devices. The devices that can be tested with ETNA platform include High voltage devices, System on Chip (SoC), Micro Electro Mechanical Systems (MEMs) and Memories. Within the family of SoC devices, EDA is focused on Smart power, Logic SoC and SoC with embedded memory. For High Voltage we have a specific platform called MOSBTS-M Test System. In addition…

By interpreting SiC and GaN mega-trend, EDA designed SocrATE project, putting in place all the skills to develop an exclusive product, in line with the expectations of the AUTOMOTIVE market such as Testing Coverage, Quality and lowest Test cost. System features SocrATE is a complete Burn-in test system designed specifically to meet the needs of cost-sensitive volume manufacturing of current and next generation SiC, GaN and High Voltage devices. SocrATE offers true site-independent test across a broad range of software-controlled configurations. The innovative architecture backs each of the system's 1800 or 3600 sites with a fully independent Test system. Prober…

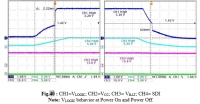

UBTS / VBTS / VBTS-M Series Starting with dedicated BI system for Memories, Digital, Automotive and Mixed-Signal devices, the technological evolution of devices dictated by the market and the demand of increasing the test capacity have brought EDA Industries to design a powerful and innovative test system: the UBTS - Universal Burnin Test System. This series is based on reprogrammable Microprocessor and FPGA firmwares, so that the same HW platform can be SW reconfigured as a Digital, Mixed-Signal, Memory tester.Moreover, it allows a continuous development of new features and upgrades, that can be easily released/updated just by deploying a FW…

MOSBTS-M on ETNA platform enables many different Test executions for SiC and GaN, discrete and Power Modules: - HTRB/HTGB - H3TRB - DHTOL - LTOL - PTC More than 50 ETNA MOSBTS -M are currently installed in Mass Production. For info, pls send a direct request to This email address is being protected from spambots. You need JavaScript enabled to view it..

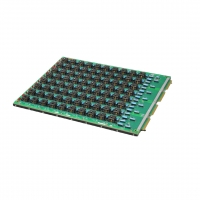

EDA designs and produces Burn-in Boards. EDA BIB Standards are: STANDARD EDA HD Standard format: 570mm x 440mm (22.437” x 17.322”) LONG format: 570mm->640mm 480 finger contacts (4 x 120) Max current : 55 A STANDARD EDA HD/H Additional 44 power contacts (2 x 22) Up to 108 A on VBTS-M system STANDARD EDA HD/H3 Additional 11 power contacts (1 x 11) Single DUT Thermal Control (iSocket feature) STANDARD EDA HD/H High Power Additional 504 High Power connectors (4 x 126) Up to 108 A + 640 A on VBTS-M-HP system EDA is also capable to design and produce other…

Analysis and design of electronic boards and test programs for the Qualification of new semiconductor devices in respect of customer design spec and reliability engineer HTOL PTC HTRB THB IOL StressTest HAST CHIPBOARD BURN-IN TDBI Test During Burn In Support to start-up of qualification test of new semiconductor devices at customer reliability labs Analysis and design of electronic boards and test programs for the BI or TDBI of new semiconductor devices in respect of Customer request Support to start-up of production of new semiconductor devices test program at customer production plants Infrared thermal analysis for correct trial temperature set Signal…

In addition to the test systems and burn-in, EDA Industries produces a series of equipment to manage the other operations of the electronic devices' qualification and production cycles.Those products are: Engineering Test Station (ETS) Pre Burn-in Test Station (PBTS) ENGINEERING TEST STATION (ETS) Description: ETS stays for Engineering Test Station.It is meant to be used for Application Development, BIB design debug, Test program verification, etc.It gives a direct access to the top of the Burn-in Board to easily insert/remove device, running/stopping tests, measuring voltages, currents, waveform, etc. directly on the BIB while the test is running.The top roof/tray of the…

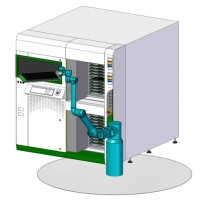

When you begin working on the development of an automated Burn-in area there are a lot of argument to be coordinated and consolidated: Automatic Bib warehouse, AGV fleet management, SW, etcc. For these reasons it might be preferable, more practical, to choose the most flexible solution in the market: The COBOT. Equipped with a light ring, it immediately signals its status or draws the attention of operators. Clean room ISO 14644-1 Class 6 certified, and protection from dust and water splashes IP54. Advanced security level PL e - CAT 4. Smart-Vision system EASY INSTALLATION in many different directions (front of…